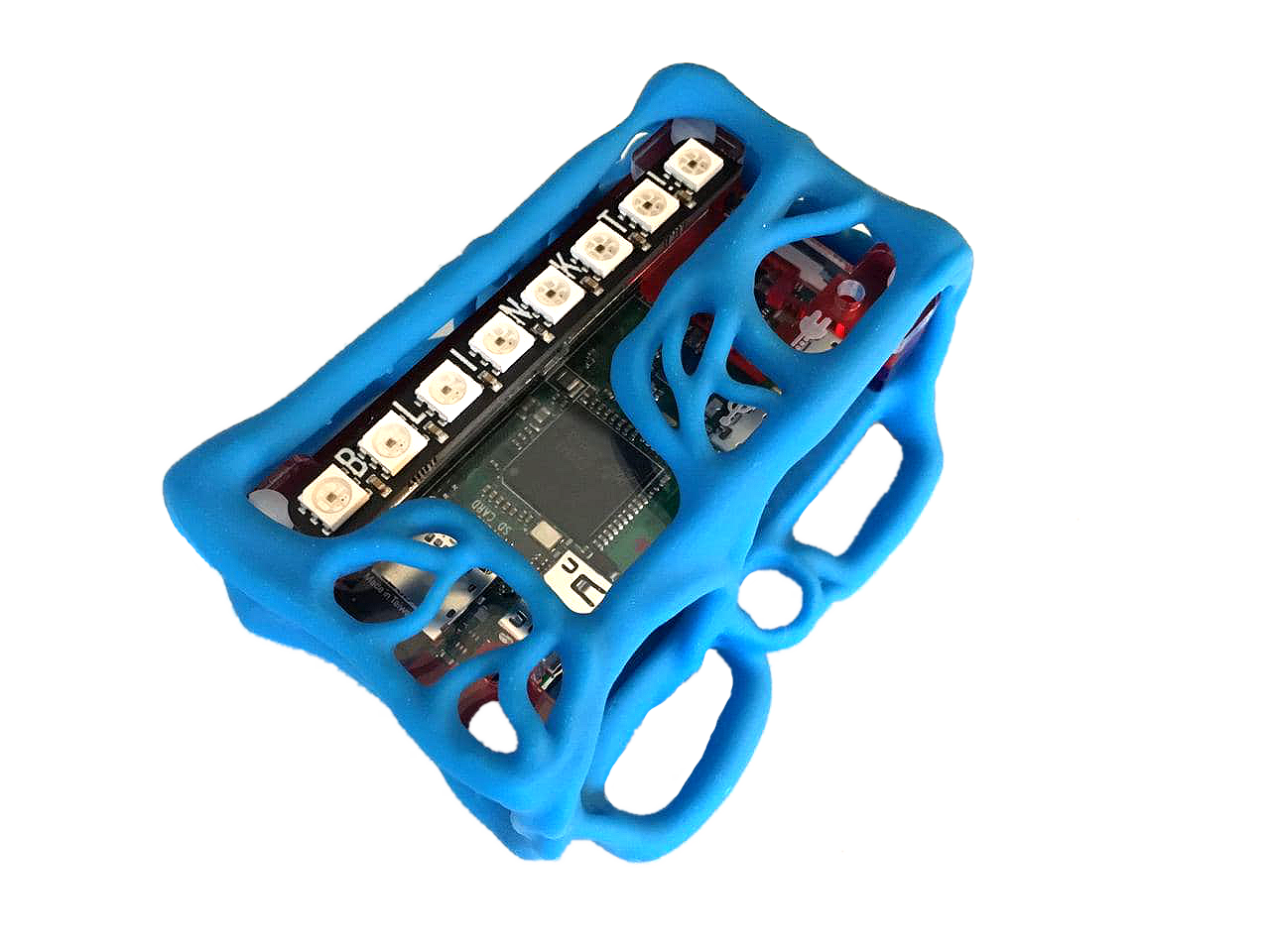

I created this 3D printed Rasberry Pi Zero case as part of a project for Computer Science 601 - Wearable Applications. This project used a flex sensor combined with a Raspberry Pi 3 Model B to detect forward head position. The Pi 3 was coded via OSC to communicate with a networked, battery powered Pi Zero W with an LED array to provide positive or negative feedback via a forearm mounted device.

The design process for this project began with the assembly of the Pi Zero W, the PiBow Zero Case and the Pimoroni Blinkt LED strip. Next, I measured the size of the device and used these values to create a boolean box in Blender that would be used to “cut” the correct space into the 3D sculpted case. I also photographed the assembled Pi Zero from a top view to use as reference while sculpting. 3D sculpting was conducted in Virtual Reality using an Oculus Rift S headset and Adobe Medium software. The Blender boolean box and the image reference were imported into VR, and locked together to form a base for the sculpture. The enclosure design was inspired by the interlocking branches and roots of banyan trees. It was important for the design that all the Pi ports were accessible while in the case, and a small loop was included to use for discrete cable management of the Pi’s power cable. When the design was complete, the boolean box was used to cut out the center of the enclosure so the Pi Zero would fit perfectly inside.

The case was printed in 8 hours and 30 minutes using a Formlabs Form 2 resin printer, and a cyan tinted color kit resin. The advantage of pre-colored resin is that it can withstand wear and tear better than painted prints, and is therefore ideal for color prototypes. Preform (Formlab’s slicing software) was used to make sure the scale of the print was correct, and the print was oriented so that the supports would mostly be on the bottom of the case, requiring minimal cleanup.